Start by saying you understand fabrication machinery. If you have been asked how you know about the metal fabrication machinery, you will come up with how metals are formed according to the specific size and shape. Find out the different types of metal fabrication machines.

Common types of fabrication machinery

These are the three used types of fabrication machines you can find in every machine shop:

Waterjets. It is the most cost-effective and useful method to cut various materials. The industrial machine tools use abrasive substances and water to cut virtually anything, such as:

-

- Aluminum

- Carbon steel

- Copper

- Brass

- Glass

- Stainless steel

- Plastics

- Ceramic

- Stones and more

The machine is versatile. It has almost no heat generated to the workpiece, unless you are cutting steel at least 2-inch thick. Waterjets use high-pressure pumps reaching speeds of anywhere from 30hp-100+ hp, forcing the water out by the nozzle to cut the material. These jets have an abrasive hopper system with a metered flow of granular abrasive to aid in cutting the above-mentioned materials.

- Waterjet is the most versatile and the best fabrication machinery to invest in, whether for personal or business use.

- Press brakes. It is the sturdiest and most dependable bull in the field. It has only one function; it is bending metals. Press brakes are used to secure the workpiece on the bed while the ram descends upon it. Using the tonnage, it accurately bends the metal according to a specific degree. There are different types of metals that are fabricated by this machine, including:

- Steel

- Aluminum

- Brass

- Sheet metal

Press brakes rate by the tonnage (pressing capacity) and the bed length that dictates the complete length of the workpiece that fits in the bending zone. The tonnage capabilities range anywhere from 25-1,000 tons. The smallest bed length begins at 4ft. whereas the longest reaches the length of 30ft. Press brakes have four different types:

- Hydraulic

- Mechanical

- Pneumatic

- Servo-electric

The hydraulic and mechanical press brakes are the most used, and much more user-friendly. Mechanic brakes are ideal for lower tonnage requirements as it requires low maintenance and doesn’t break the bank. The hydraulic brake is the ideal machinery for higher tonnage capabilities, which is also the most efficient and powerful type of machine, especially for a larger job using thick metals.

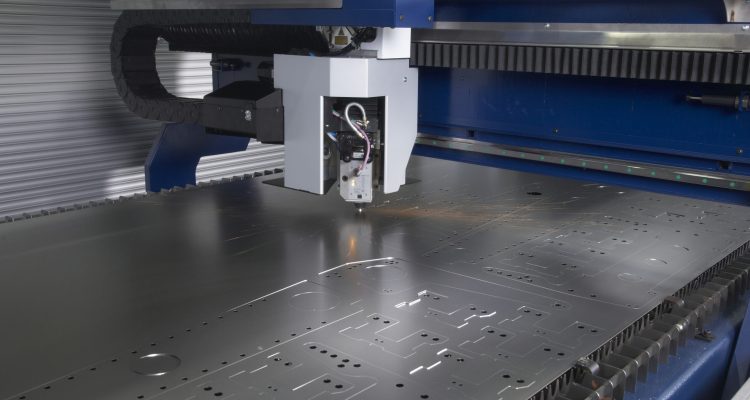

- Laser systems. It is also called laser cutting systems, most common applications that lasers are used for:

- Cutting

- Marking

- Surface treatment

- Welding

It is fabrication machinery that works on high-demand operations that require high precision for cutting works, such as for:

- Automotive

- Aerospace

- Shipbuilding

- Electronics

- Medical industries

Laser systems use thermal energy for removing material from the workpiece through:

- Melting

- Vaporizing

- Blowing

- Burning

The machine makes the level of precision possible.